What is an ERP system and how does it help business?

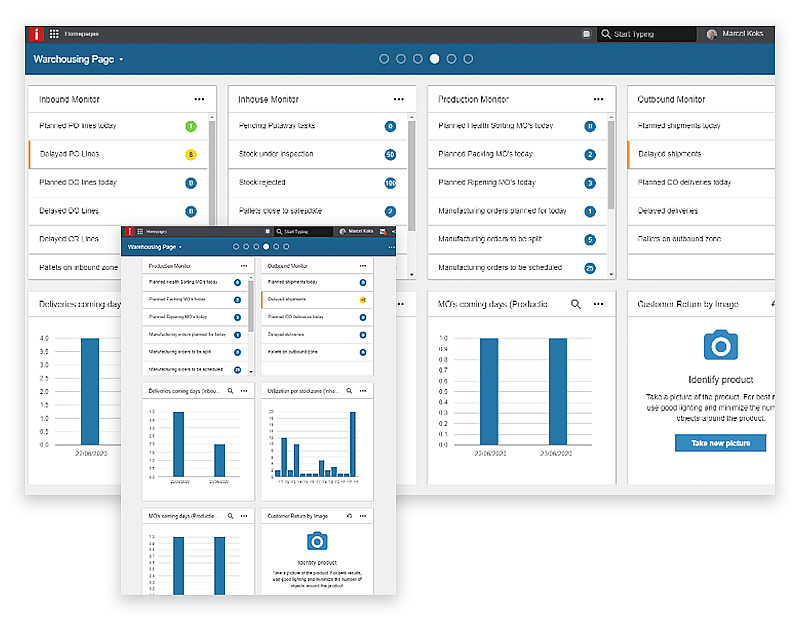

ERP systems are key to the success of modern digital businesses of any size. They're agile, secure, and data-driven tools that handle important tasks like procurement, project management, operations, financials, and sales.

Get ahead of the game by adopting an ERP solution that suits your business needs today.

undefined

undefinedWhat is an ERP system and how does it help business?

ERP systems are key to the success of modern digital businesses of any size. They're agile, secure, and data-driven tools that handle important tasks like procurement, project management, operations, financials, and sales.

Get ahead of the game by adopting an ERP solution that suits your business needs today.